A couple of months ago I received an e-mail from a Malaysian colleague. Two of his operators needed some training in Visual Testing (VT). Visual Testing is not really a popular NDT method in Malaysia yet. But for VT being the first NDT technique generally to be applied to each inspection process, he was eager to get some of his staff trained and certified according to ISO 9712.

For those of you thinking:

Hang on, Visual Testing is pretty simple stuff. Cannot everybody with a 20⬠borescope just do it?

Of course, every NDT operator could do it like that, but then there will be two operators testing the same weldings and coming up with two different results. Who really wants that?

Advantages of VT

NDT visual inspection is usually the first NDT method to be used. Certainly not as fancy as advanced techniques, it is nonetheless the first step to determine which method to use in the further inspection procedure.

But of course, VT goes much deeper than this being an established NDT method itself. Coming along with norms and standards detailing the inspection procedure and evaluation process as well as powerful tools.

The market for visual inspection tools has experienced an amazing development in recent years shifting away from rigid to flexible borescopes based on optical fibres or video borescopes.

Depending on the used tools and equipment, VT is certainly not as incredibly cheap as it used to be but it is still a very cost-effective surface testing method especially given the powerful advantage of flexible borescopes in reaching hidden surface areas.

If properly applied in the whole NDT process and given the advantages of flexible borescopes, it might be even more cost-effective now.

The VT course

The two trainees, Yusnisyam and Kamal, were not new to NDT at all. Both had a solid background as operators and even as NDT trainers in Radiographic Testing (RT), Magnetic Particle Testing (MT) and Penetrant Testing (PT).

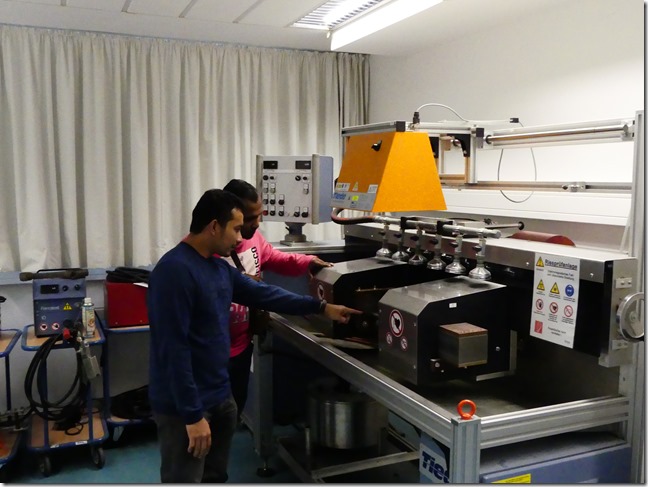

Additionally to training in VT and certification according to ISO 9712 we put together a tailored course covering the hands-on usage of VT tools, preparing the workplace and choosing the right procedure and inspection standard.

Yusnisyam and Kamal already had some good knowledge of welds which is a great help for the actual inspection process. As with any NDT method, a good knowledge of the object to be inspected is extremely important. Nothing beats hands-on testing experience to become a great operator but a solid foundation is still needed. Thatâs why we included Materials Technology into the course in order to give both a head start.

The Advantage of the Course

Having NDT colleagues from overseas in our centre was a great opportunity for us as well to get some valuable feedback on our course. As good trainers, everybody knew that the bread and butter of each course (tools, procedures and standards)

There is always the question of how training is actually delivered and how to strike a balance between covering extensive content and keeping a learning-friendly atmosphere which doesnât burn the students out after a long day (Letâs face it: After 5 hours of extensive and challenging new content, anyoneâs brain no longer functions as well as it did in the first hour ).

It is the overall package with the many small details (daily dummy qualification) which makes a good training great.

And who knows, maybe one day the Yusnisyam and Kamal will not only be Visual Inspection operators but trainers. The potential and the first step is certainly there.

Stefan Kessel